Balance maintenance needs today with modernisation for the future.

For heavy industry businesses, ageing industrial water treatment infrastructure and equipment present significant daily challenges. Water treatment processes are a crucial part of heavy industry operations. Any risk of system failure can halt production entirely. Yet, many water treatment plants have served for decades and are reaching critical operational milestones. Or, in numerous cases, operating beyond their intended lifespan.

With ageing water plants posing a substantial and growing risk to business continuity, the potential financial impact is severe. As quoted in a recent report by Siemens1 downtime can cost as much as €50 million a year in a heavy industry plant - 1.6 times higher than in 2019.

This threat creates an urgent need for solutions beyond routine maintenance. But while modernisation is ultimately crucial, implementing new technologies and facility upgrades is particularly challenging amid current economic uncertainty. Plant operators must balance the urgent need for innovation with practical financial constraints.

The hidden costs of ageing water infrastructure: What industry engineers need to know

For heavy industry engineers managing water systems, ageing infrastructure creates a complex web of challenges that impact both daily operations and long-term sustainability. Let's dive into the key issues that engineering teams face when dealing with ageing water treatment systems.

-

Escalating maintenance demands and costs

The financial burden of maintaining older water infrastructure increases with time. Maintenance complexity and costs typically surge once systems operate beyond their designed lifespan.

-

The parts procurement challenge

One of the most frustrating aspects of managing ageing water systems is sourcing replacement components. There is a growing crisis in spare parts availability, with many original manufacturers no longer supporting older systems. This forces engineering teams to seek expensive custom solutions or rely on temporary fixes that may compromise system efficiency.

-

Navigating modern compliance requirements

Today's environmental regulations present a particular challenge for ageing water infrastructure. Older systems often struggle to meet current water quality and discharge standards.

-

Dealing with declining system performance

The older water treatment plants get the less reliable they become, a point that is particularly acute during late-life stages. This decline affects not only water quality but also overall plant efficiency.

-

Strategic resource management

Facing global economic turmoil, perhaps the biggest challenge lies in balancing immediate maintenance needs with long-term modernization goals. With limited budgets and resources, engineering teams must make strategic decisions about where to invest their time and capital for maximum impact.

These challenges underscore the need for innovative solutions in industrial water treatment, particularly flexible options that can bridge the gap between current operations and future upgrades.

A flexible solution for a complex problem

Mobile water treatment services have emerged as a key strategic solution to these infrastructure challenges. This approach enables industrial facilities to maintain production while systematically upgrading their water treatment infrastructure, effectively balancing immediate operational needs with future sustainability goals.

What is a mobile water service and how does it work?

A mobile water service provides emergency, planned or even multi-year water treatment solutions through portable, containerised systems that can be rapidly deployed to any location. These self-contained units have a relatively small footprint but are equipped with advanced filtration, purification, and treatment technologies that can process water from various sources to meet specific quality requirements.

The service works by delivering and setting up these containerised treatment systems on-site, where they can quickly begin treating water for industrial processes, emergency situations, or supplemental supply needs. The units are operated and maintained by water treatment specialists, requiring minimal infrastructure or manpower from the client site.

How do mobile water services resolve complex ageing water infrastructure problems?

Mobile water treatment solutions serve as a modern answer to ageing industrial water infrastructure challenges. Fast and flexible in set-up, a mobile water unit can be added on site without operational disruption. These industrial-grade portable water treatment systems can be rapidly mobilised to supplement or temporarily replace outdated water treatment equipment, providing essential support during infrastructure emergencies, scheduled maintenance, or critical system upgrades.

From emergency water demineralisation to advanced mobile reverse osmosis systems and innovative electrodeionisation units - these solutions effectively bridge ageing infrastructure gaps with modern water treatment technology often resulting in environmental, cost and safety benefits.

This cost-effective mobile water treatment approach minimises facility downtime and operational risks, allowing organisations to strategically phase their water infrastructure upgrades while maintaining consistent water quality standards.

Real-life success stories

European chemical company achieves €2M annual savings with hybrid approach:

A leading fine and specialty chemicals manufacturer tackled ageing infrastructure challenges through an innovative hybrid approach. By combining existing plant refurbishment with mobile water services, they achieved 24/7 production of 150 m³/h demineralised water. The solution included ultrafiltration (UF), reverse osmosis (RO), and ion exchange systems, delivering annual cost savings of €2 million while reducing environmental impact through water recycling.

Oil & gas refinery modernisation saves €1.2M with mobile water treatment:

A major European refinery successfully transformed its water treatment infrastructure using mobile RO and EDI technology. The temporary solution delivering 210 m³/hour of demineralised water, compared to traditional mobile supply of ion exchange trailers, eliminated 44 annual trailer movements and avoided 125 tons of CO₂ emissions. The innovative approach resulted in €468,500 yearly savings while eliminating chemical usage and improving site safety.

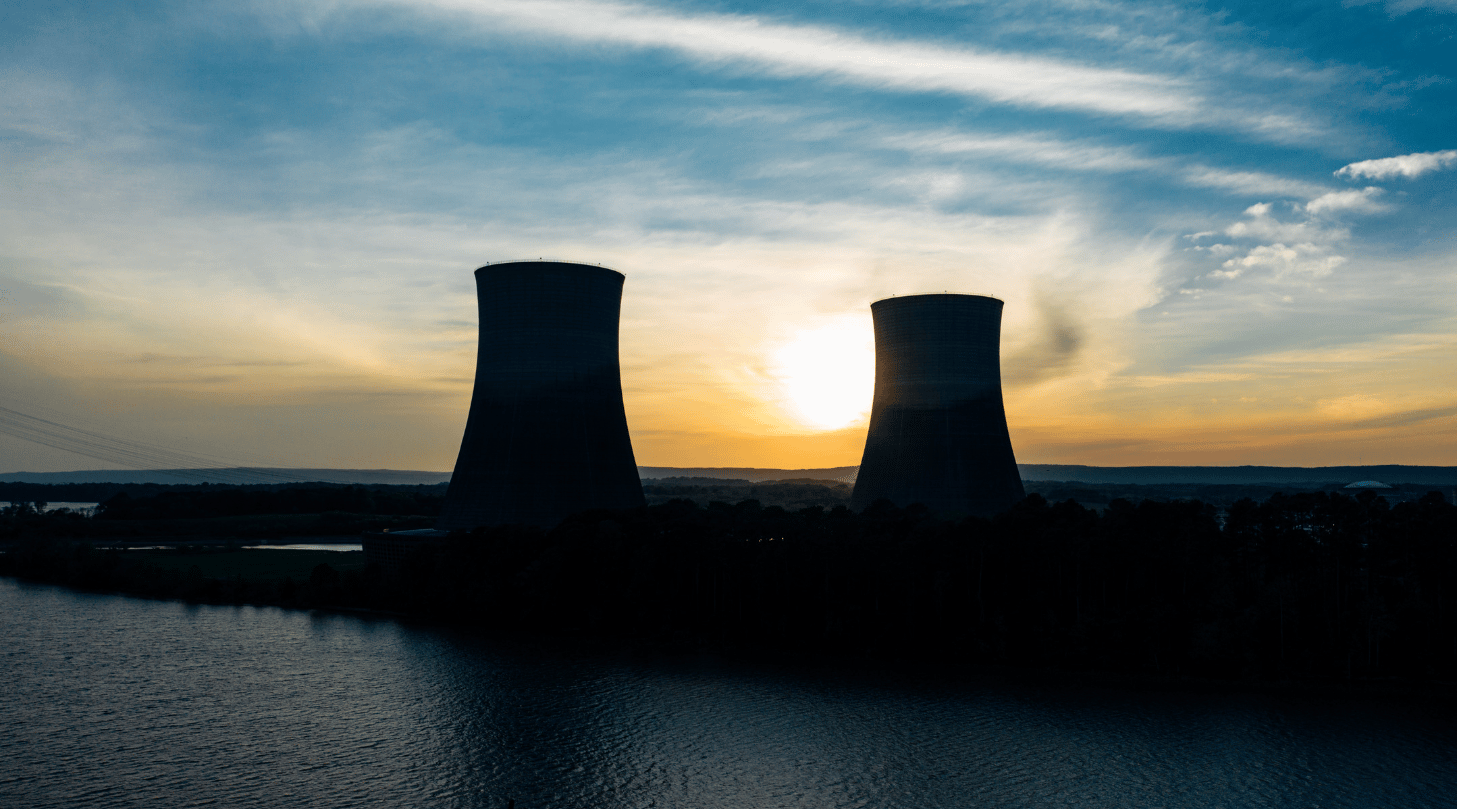

Nuclear power station prevents €1.2M daily losses with emergency water services:

When faced with critical feed water issues in their 30+ year-old water treatment plant, a nuclear power station avoided costly downtime through rapid deployment of mobile water services. The pre-established Emergency Water Plan enabled smooth implementation of temporary units, maintaining steam generation operations and preventing potential losses of €1.2 million per day during repairs.

Revolutionise your approach to water management

Mobile water services have emerged as a proven strategy for industrial facilities facing complex ageing infrastructure challenges. Success stories from heavy industry show how this flexible solution ensures operational continuity while meeting environmental compliance.

By implementing mobile water services, industries can modernise their infrastructure, reduce costs, and achieve sustainability goals without disrupting production.