Elena Torresi is a Sales & Process Engineer at Veolia Water Technologies. She specialises in the process of designing biological treatment for municipal projects based on MBBR and hybrid technologies. Elena recently presented an insightful webinar for us and here she provides a summary of the session.

The problem with ammonia-png-3.png?width=1230&height=518&name=Blog%20Headers%20(1)-png-3.png)

The discharge of a water source with high concentration of ammonia can have a negative impact on the environment. Aside from causing eutrophication and hypoxia in the recipient water, it can also affect the pH of soil and damage leaves if used as irrigation. In some extreme scenarios, certain natural habitats can even be lost, which has a knock-on effect on wildlife and the food chain.

What is MBBR?-png-1.png?width=1230&height=518&name=Blog%20Headers%20(2)-png-1.png)

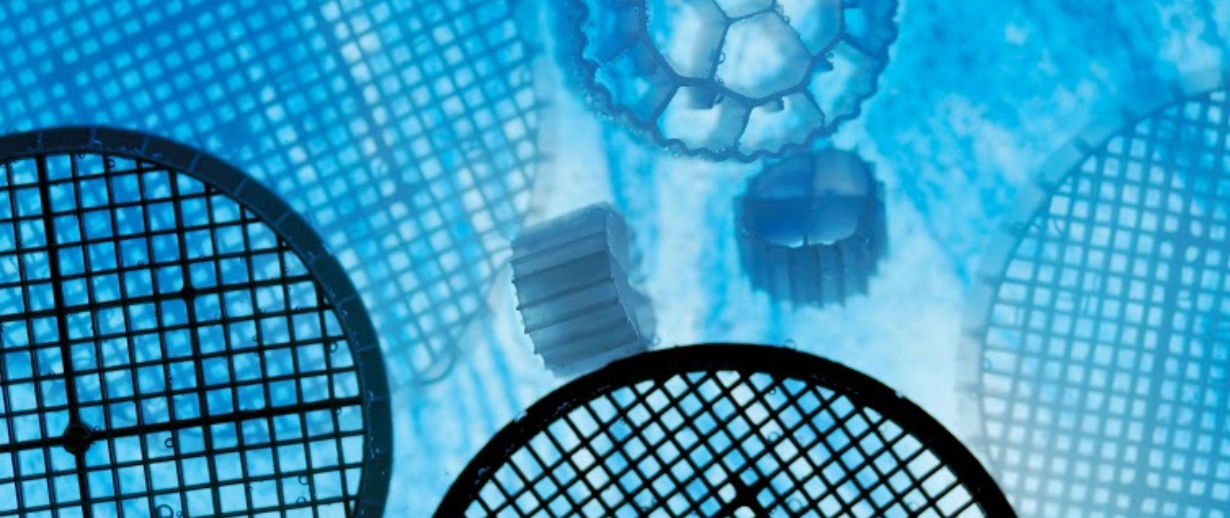

MBBR (Moving Bed Biofilm Reactor) treatment is a biological aerobic wastewater treatment process that utilises active nitrifying biofilm growing on carriers made from virgin or recycled High-density polyethylene (HDPE). Each of these carriers has a large surface area on which the bacteria can grow under optimal process conditions. Aeration ensures that the carriers are constantly kept in motion, allowing the bacteria to break down the organic material and the ammonia present in the wastewater.

Key challenges and considerations -jpg-1.jpeg?width=1230&height=518&name=Blog%20Headers%20(4)-jpg-1.jpeg)

When looking to implement a water treatment system for the removal of ammonia, there are a number of considerations that need to be made. Firstly, nitrification rates depend on the concentration of ammonia targeted in the effluent – the lower the targeted level of ammonia, the lower the nitrification rate. As such, in instances where the influent has a low level of ammonia, but not low enough, the technology will require a larger footprint to accommodate the low ammonia rates.

There may also be circumstances where there is a prolonged low level of ammonia going to the tertiary technology. As a result, it will be difficult to develop and maintain the nitrifying bacteria.

Conversely, a peak flow event such as a storm can cause the ammonia level to be two to three times greater than normal. Therefore, the treatment technology has to be robust. It will also need to have a good control strategy in place to deal with the peaking events.

Advantages of MBBR

MBBR technology can provide an effective solution to these challenges. In order to manage the low nitrification levels, the biofilm carriers have a high surface area, allowing the nitrifying biomass to grow. This ensures the system runs efficiently, allowing a compact design.

Control of the aeration system can also provide the solution to peak ammonia loads. When ammonia levels are high, a higher quantity of oxygen can be delivered into the tank, which in turn will increase nitrification capacity. Conversely, when ammonia load is low, aeration can be lowered, minimising energy costs.

MBBR has several other advantages. Thanks to its simple design, existing MBBR systems can easily be upgraded to increase plant capacity by addition of extra media.

It is also a downstream solution that has a minimal upstream impact because it is independent from sludge recirculation. Therefore, there is no need for a recirculation pump or SRT control as in conventional biological systems.

Finally, all the activity occurs on the media, meaning there is low solids concentration in effluent from the MBBR process. Therefore there is often no need to incorporate solid separation after the MBBR (if there are no stringent suspended solids consent) .

Following specification, our team can continue to offer support to ensure that the plant runs as efficiently as possible.

To learn more about our MBBR technology, contact one of our experts today.